Understanding Smart Manufacturing

A technology-driven technique called "smart manufacturing" uses equipment that is usually connected to the Internet to track the production process. The objective is to find ways to automate processes and use data analytics to boost industrial efficiency.

The Industrial Internet of Things is used specifically in smart manufacturing (IIoT). Sensors are embedded in manufacturing equipment during deployments in order to gather information about the machines' performance and operational state. Previously, the data was often stored locally on individual devices and only used to determine the root cause of equipment problems after they had already occurred. Manufacturing engineers and data analysts can now look for indicators that certain parts might fail by examining the data coming from each of the machine units in a factory, or even across numerous sites. This makes it possible for preventive maintenance to stop unscheduled downtime.

Background & Evolution

The advent of new technologies like 3D printing (additive manufacturing) and artificial intelligence led to the emergence of the term "smart manufacturing". The term "smart manufacturing" encompasses a number of related concepts, including "digital manufacturing" and "cyber manufacturing." Global standards are currently being created to further define smart manufacturing techniques.

Business Benefits of smart manufacturing

Smart manufacturing procedures significantly improve the manufacturing sector in two areas: asset management and quality assurance. While the introduction of sensor technology ensures product quality and production efficiency, remote monitoring ensures that factories can concentrate on making products rather than repairing machines. Continuous operational improvements made possible by smart manufacturing boosts output while cutting expenses. Machine learning enables self-monitoring and predictive maintenance, which lowers downtime and repair expenses. Furthermore, the ability to mass personalize items, create new products and services, and respond to changing client requirements is made possible by real-time understanding of the condition of production equipment and raw materials. Manufacturers can also look for patterns in the data to see where manufacturing is slowing down or using resources inefficiently. The data can be used to run simulations of various processes in order to determine the most effective ways of doing things.

Smart Manufacturing Techniques

For the total network of connected production devices to create competent and lucrative operations, smart manufacturing technologies aid in spotting issue areas.

A potent smart manufacturing technology that supports production is “digital twins”. Before a physical prototype is made, an identical virtual version of the product or system is created as a digital twin. Manufacturers can do simulations, iterations, and testing on the design of a product in this virtual environment to establish feasibility before exorbitant production expenses are paid. Digital twins speed up product development, lower costs, and eliminate unscheduled downtime. Digital twin adoption is encouraged by the growing use of IoT platforms, cloud platforms, 3D printing, and 3D simulation software.

Many manufacturing environments are implementing AI-capable robots as well. Robots that were programmed to do certain jobs were previously used in typical industrial facilities. With the advent of smart manufacturing, there are now intelligent robots on the factory floor that are connected to sensors to collect data. Decision-making based on perception is now possible thanks to AI robotics, which was previously not conceivable when using simply rule-based algorithms. Predictive maintenance using AI in smart manufacturing can be used to identify machine performance, equipment failures, and other operational circumstances in real-time.

Challenges Faced By Smart Manufacturers

The widespread adoption of smart manufacturing still confronts challenges, particularly for small-to-medium manufacturing businesses (SMEs), because of the expense and lack of employee training. Since it is challenging to incorporate IIoT into existing or outdated systems, smart manufacturing is not as widely used as some other smart technologies. To make the best use of sensors and related technology, smart manufacturing concepts must be incorporated into the design of a manufacturing plant.

Connectivity Requirements

Every equipment, device, and process in the IIoT is connected using data communication protocols. Each piece of industrial machinery has sensors built in that can produce data and transmit it to the cloud or the software system using communication networks. Connectivity that is dependable, secure, and frictionless is essential for such digital transformation.

There are a number of connectivity requirements that must be met before data can be received to increase operational efficiency. It's important here to assess connectivity options carefully and select the one that will connect the devices and systems but also enable smooth communication with the least amount of upkeep.

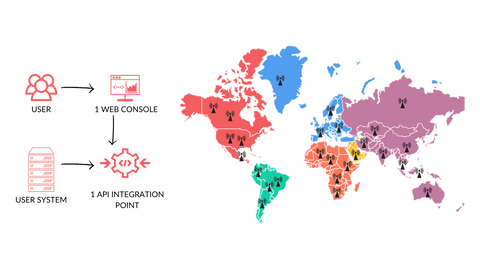

This is why ConnectedYou offers reliable multi-network coverage and better delivery of network connectivity as per business requirements.

Why ConnectedYou?

We orchestrate the critical components that include - eUICC-enabled SIMs/ eSIMs, global IoT/ M2M connectivity, unified monitoring & management, and remote SIM provisioning capabilities into a single solution as a one-stop-shop. Here’s why our product is the best solution for your enterprise -

- The largest aggregation of 2G, 3G, 4G, 5G, LTE-M, and NB-IoT networks

- Connectivity options for countries with permanent roaming restrictions

- Transparent Pay-As-You-Go pricing without hidden charges or minimum commitments

- Connectivity without throttling for best experience

- Local/ regional breakouts globally to achieve desired latency

- Single contract enabling hassle-free multi-supplier sourcing without lock-ins with any connectivity provider

- Unified platform to manage your IoT/ M2M SIM cards irrespective of the connectivity supplier

- Capability to switch connectivity suppliers remotely without SIM replacement and without any additional transaction costs

- Central support desk for all connectivity issues

We would be very keen to hear about your challenges, help you and share your pain with our ecosystem of suppliers and partners to deliver exemplary service for your enterprise. Get in touch so that we can ensure and offer a future-proof IoT roll-out. Write to us at sales@connectedyou.io